Overall aim

The transition towards a circular society requires us to design new materials and chemistries. This grand challenges requires radically new ways of doing chemical research. The National Growth Fund has recently allocated 97 million euro Big Chemistry research consortium to build an automated Robotlab that combines automated chemical experiments with AI. The Robotlab’s aim is to accelerate the discovery of complex molecular systems and formulations for biomedicine and materials science. In such complex molecular systems, the properties of the system cannot be traced back to properties of the individual components. You can think of the taste of beer, texture of a coating, or, indeed, a living cell!

A fully functional Robotlab requires a new type of ‘chemical AI’. We will need to develop algorithms and new ways of doing chemistry to predict the properties of complex. molecular systems. For this, we need data. Lots of data. For this reason, automated experiments and automated analyses are crucial. Realizing these automated chemical platforms is, however, not straightforward and requires unconventional approaches.

To address this challenge, the Big Chemistry Robotlab uses robots and artificial intelligence to accelerate the discovery of complex molecular systems and formulations for biomedicine and materials science. We focus strongly on finding new ways to study, quantify and understand how molecules interact with each other. Depending on the project, there is a more academic focus, or close collaboration with industrial partners.

Challenge 1

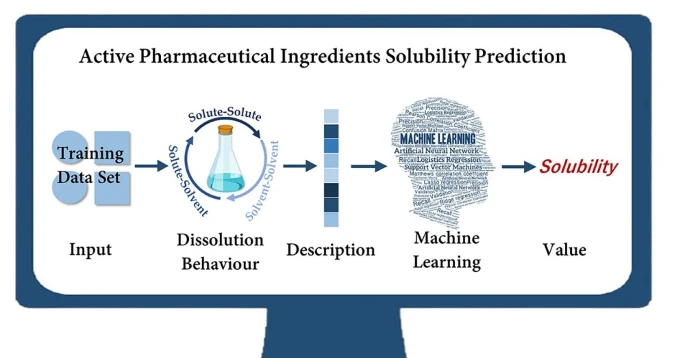

Predicting the solubility and volatility of molecules in water

The solubility and volatility of molecules is of fundamental importance in almost every

application in food and medicine. For example, drug molecules must be soluble in water,

otherwise they cannot be administered to the patient, and the taste of alcohol-free beer

is largely determined by our perception of volatile compounds. However, despite many decades

of computational studies, we cannot predict the solubility and volatility of molecules. In

this project we will establish a high throughput experimental platform to determine these

properties of 1000’s of molecules in water and. By using both experimental data as well as

databases, we will train AI algorithms to derive new rules correlating molecular structure

with solubility and volatility.

The solubility and volatility of molecules is of fundamental importance in almost every

application in food and medicine. For example, drug molecules must be soluble in water,

otherwise they cannot be administered to the patient, and the taste of alcohol-free beer

is largely determined by our perception of volatile compounds. However, despite many decades

of computational studies, we cannot predict the solubility and volatility of molecules. In

this project we will establish a high throughput experimental platform to determine these

properties of 1000’s of molecules in water and. By using both experimental data as well as

databases, we will train AI algorithms to derive new rules correlating molecular structure

with solubility and volatility.

Contact person: Will Robinson

Challenge 2

Discovering catalytic activity and innovative material properties in small peptides

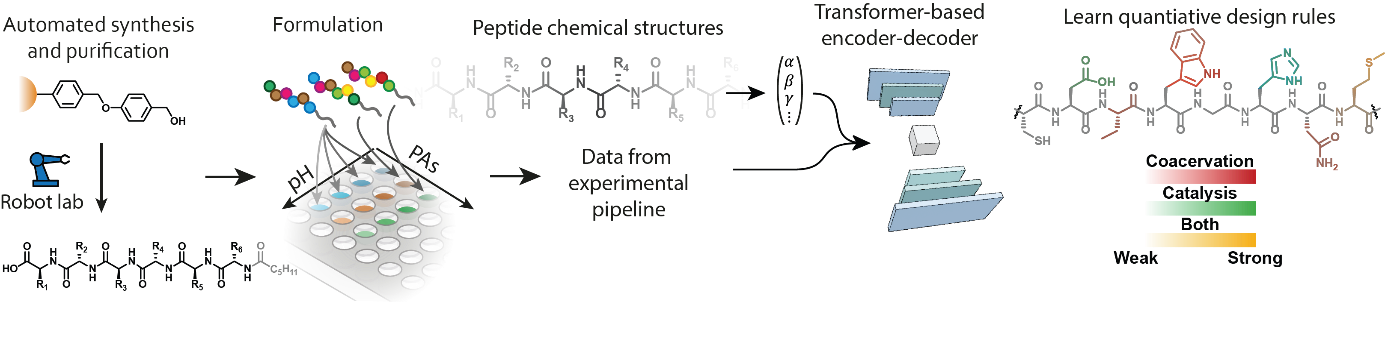

Nature uses proteins as key building blocks for structure and chemical transformation.

Collagen is a particularly interesting example, where a tripeptide repeat sequence yields an

enormous variety of materials with different properties (toughness, elasticity, strength. In

addition, enzymes display an unparalleled range of chemical conversions, activity and selectivity.

If we could access small peptides with suitable repeat units, we envisage the discovery of a wide

range of new catalysts or soft materials build from peptides. Unfortunately, the sequence space is

enormous (for a heptapeptide there are already over 1 billion different sequences). We therefore need to develop

new methods to rapidly move through sequence space. We combine automated peptide synthesis with

high throughput screening of properties (catalytic activity, phase separation, self-assembly into

fibers) and AI. The objective of this project is to develop algorithms that can predict peptide

properties based on sequence. Students interested in synthesis of peptides, physical characterization of

bio-based peptide materials, or in implementing machine learning and AI to predict new peptides with better activity

are encouraged to contact us for internship opportunities.

Nature uses proteins as key building blocks for structure and chemical transformation.

Collagen is a particularly interesting example, where a tripeptide repeat sequence yields an

enormous variety of materials with different properties (toughness, elasticity, strength. In

addition, enzymes display an unparalleled range of chemical conversions, activity and selectivity.

If we could access small peptides with suitable repeat units, we envisage the discovery of a wide

range of new catalysts or soft materials build from peptides. Unfortunately, the sequence space is

enormous (for a heptapeptide there are already over 1 billion different sequences). We therefore need to develop

new methods to rapidly move through sequence space. We combine automated peptide synthesis with

high throughput screening of properties (catalytic activity, phase separation, self-assembly into

fibers) and AI. The objective of this project is to develop algorithms that can predict peptide

properties based on sequence. Students interested in synthesis of peptides, physical characterization of

bio-based peptide materials, or in implementing machine learning and AI to predict new peptides with better activity

are encouraged to contact us for internship opportunities.

Contact person: Mathijs Mabesoone

Challenge 3

Replacing persistent surfactants with benign, biobased alternatives

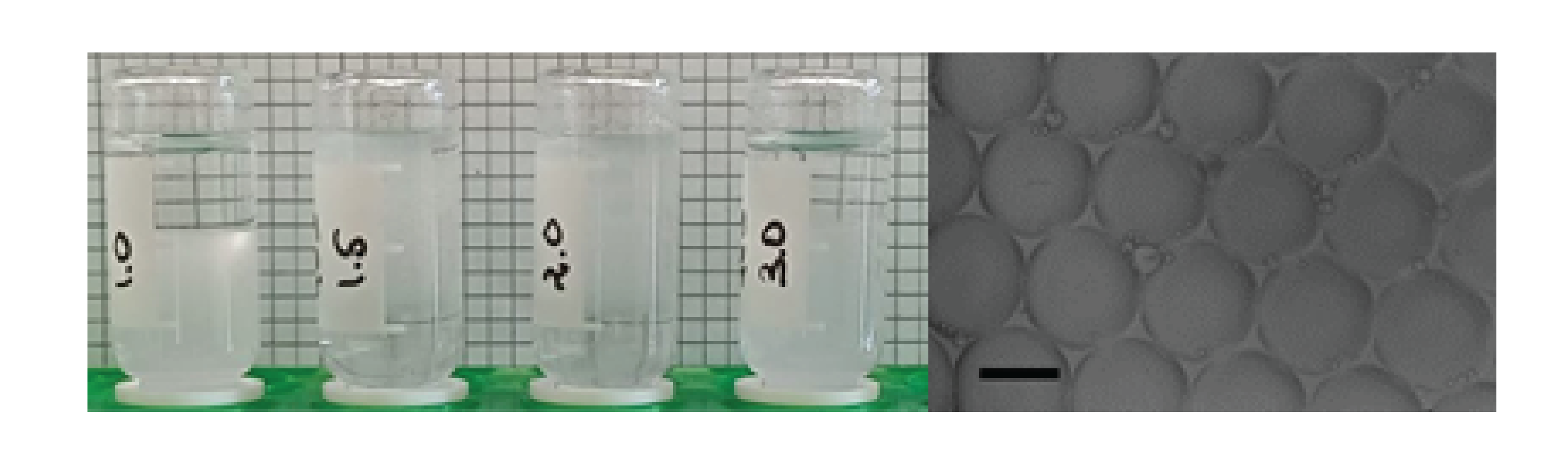

Some of the most useful chemicals are also the ones that damage our environment the most.

Fluorinated surfactants, for instance, provide us with superior waterproofing of rain jackets, non-stick

pans and fire extinguishers. However, these molecules have many unwanted biological effects and hardly degrade

when they end up in the environment. In this project, you will be working on replacing fluorinated surfactants

for microfluidics. The current methods to measure droplet stability are very tedious, so we will need to develop

new ways of generating emulsions and measuring their microscopic stability. Besides innovative experimental solutions,

we also need an AI that can propose new chemical structures of surfactants and ways of formulating them to match the

performance of fluorinated oils, but without their undesired properties.

Some of the most useful chemicals are also the ones that damage our environment the most.

Fluorinated surfactants, for instance, provide us with superior waterproofing of rain jackets, non-stick

pans and fire extinguishers. However, these molecules have many unwanted biological effects and hardly degrade

when they end up in the environment. In this project, you will be working on replacing fluorinated surfactants

for microfluidics. The current methods to measure droplet stability are very tedious, so we will need to develop

new ways of generating emulsions and measuring their microscopic stability. Besides innovative experimental solutions,

we also need an AI that can propose new chemical structures of surfactants and ways of formulating them to match the

performance of fluorinated oils, but without their undesired properties.

Contact person: Wilhelm Huck